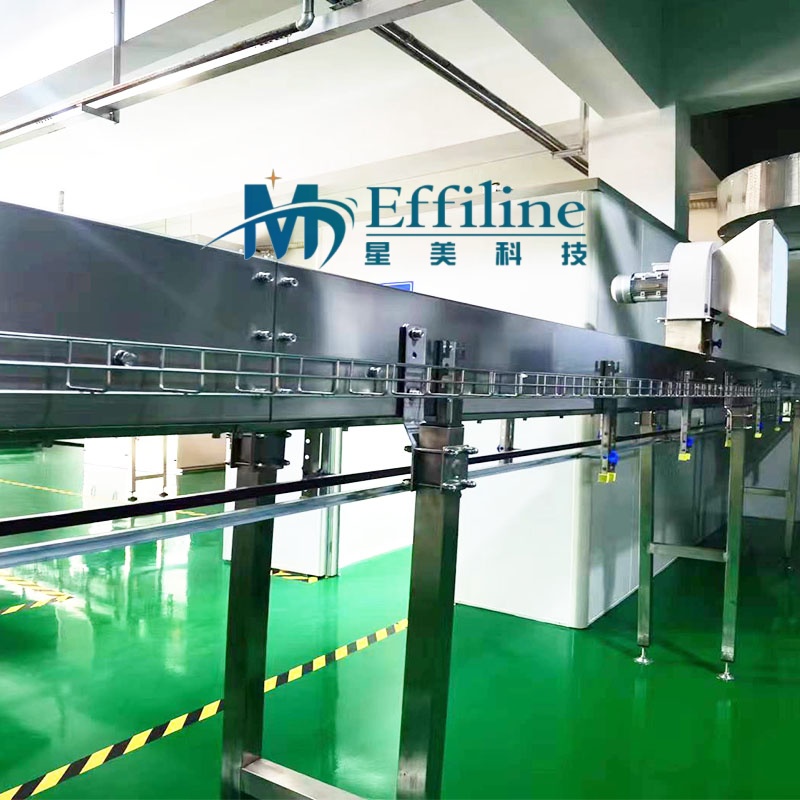

Effiline provides complete conveyor systems for PET and HDPE containers, with custom CAD layout designs tailored to each facility and application scenario to meet diverse requirements.

Our automated air conveyor supports seamless changeover between different bottle formats, featuring one‑touch lane‑spacing adjustment for rapid multi‑format switching. Controlled by advanced VFD‑PLC programs, both the air conveyor inlet at the blow‑molding machine and the inlet at the filling machine are equipped with auto‑drop devices that release bottles automatically when lanes are full.

The air conveyor transports bottles directly from the blow‑molding machine to the filling machine, enabling fully automated filling operations. Widely applied in bottled water, carbonated beverage, and juice production lines, it saves labor and significantly boosts throughput efficiency.

| Component | Function Description |

| Air Channel Body | Enclosed stainless-steel or aluminum duct housing the airflow and guide rails. |

| Neck Guide Rail | Also called bottle neck rail; supports bottles by their necks to suspend the bodies. |

| Centrifugal Fan | Generates high-speed airflow to move the bottles forward along the guide rail. |

| Adjustable Rails | Mechanism to adjust rail width for different neck diameters, manual or automatic. |

| Bottle Stopper / Diverter | Controls bottle flow, used for accumulation, merge/split control. |

| Air Filtration Unit | Optional HEPA or fine filters for ultra-clean or aseptic environments. |

| VFD Speed Control | Adjusts fan speed via frequency converter for precise control. |

| Sensors / Vision | Detects jams, missing bottles, or blockages; integrated with the PLC alarm system. |

Compatible with standard PET water lines or carbonated beverage lines

Works with manual or pneumatic guide‑rail adjustment

Air conveyor for PET bottle uses blower‑generated air power and a pressurized air duct to transport empty bottles directly from the blow‑molding machine to the filling machine. All duct structural components are made of 304 stainless steel to resist weak acids and alkalis. The neck‑guide strips are made of ultra‑high‑molecular‑weight polyethylene, offering low friction and high wear resistance for extended service life. The entire line’s electrical system is controlled by PLC, HMI, VFDs, and photoelectric sensors, minimizing bottle re‑contamination, reducing packaging costs, and saving labor.

This system features energy efficiency, a compact frame, attractive design, simple controls, easy adjustment, and effortless cleaning. It meets food‑grade sanitation standards and is an ideal solution for bottle conveying.

The PET empty‑bottle air‑duct conveyor line comprises a blower drive unit, straight ducts, curved ducts, inclined and declined ducts, merge/divert units, bottle‑drop devices, and bottle‑clamp units.

Detailed Technical Specifications:

Air conveyor cross‑section: 240 × 220 mm

Auto‑drop device at the conveyor outlet

Neck‑guide strips made of 9 million MW AST engineering plastic, continuous one‑piece design

Air filtration and regulation: 2.2 kW blower, filter housing, primary filter element, high‑quality domestic motor

Control cabinet: PLC and touch screen by Inovance; frequency converter by Inovance; air switch by Schneider Electric.

Blower: 2.2 kW at 2,880 rpm, airflow 2,840 m³/h, VFD‑adjustable, pressure 600–1,000 Pa

Capacity range: 12,000–24,000 BPH

Enhanced air filtration and protective enclosure

Ideal for pre‑filling stages of juice, tea beverages, and other mildly acidic products

- High‑level sterile air supply system for aseptic beverage lines

- Maintains bottles in aseptic conditions throughout conveying

- Equipped with hydrogen peroxide sterilization and automatic cleaning to prevent bacterial ingress

- Integrated HEPA filtration for ISO 5 (Class 100) clean‑air standard

- Suitable for cold filling, UHT dairy, functional beverages, and other high‑hygiene applications

Air conveyor pricing is determined based on your line layout. Effiline offers customized planning and design tailored to your facility, delivering a complete air conveying solution. Contact us for the latest layout proposal and quotation.