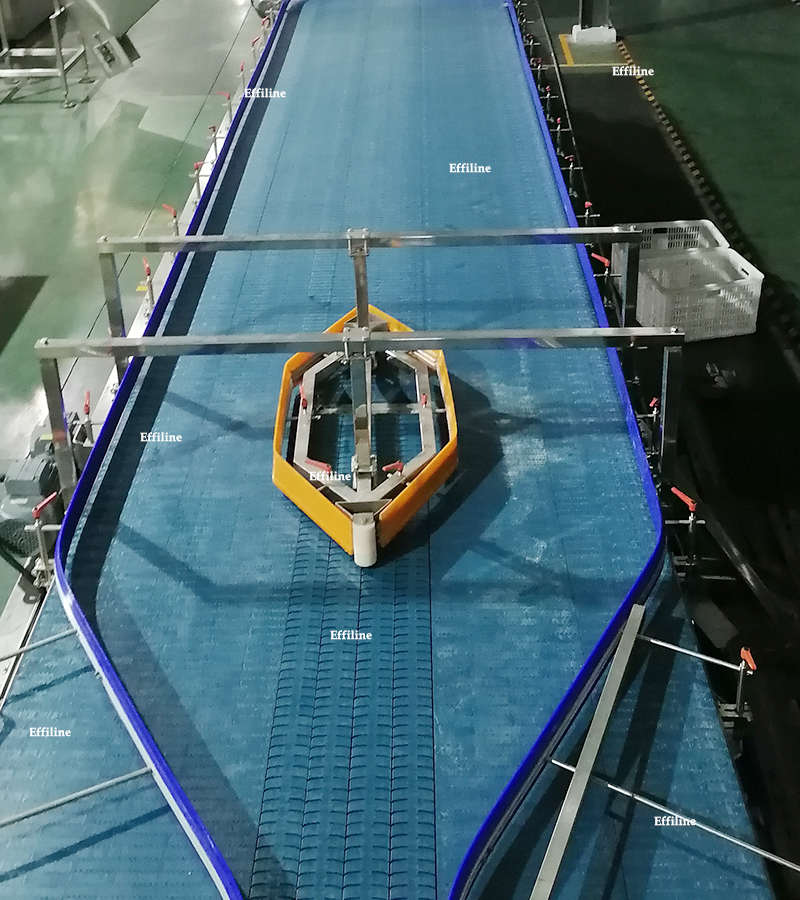

Effiline dynamic buffer platform adopts advanced dynamic storage technology to deliver over 40% more effective buffering capacity under the same conveyor length, while reducing floor space usage by up to 60%. The system dramatically lowers bottle-to-bottle pressure, achieving true zero-backpressure accumulation. With intelligent PLC control, the buffer ensures smooth bottle flow. When bottles accumulate at the front end, the shuttle cars move in sync with the flow, maintaining near-zero pressure between bottles. This contributes to an overall line efficiency of over 97%.

Zero-Pressure Buffering for High-Speed Production

Ultra-Fast Dynamic Tracking

Powered by linear servo motors, shuttle cars respond within ≤0.1s, perfectly matching the peak output of blow molding lines (up to 1200 bottles/min for 500ml bottles). The cars track bottle flow in real-time, eliminating deformation risks from traditional mechanical stoppers.

Gradient Pressure Release Mechanism

Built-in arrayed pressure sensors continuously monitor force between bottles. When pressure exceeds 15N, a multi-level buffering system activates, ensuring stack heights stay under 8 layers—protecting PET bottle integrity and maintaining filling accuracy within 0.3mm tolerance.

Smart Bottle Identification System

3D Vision-Based Calibration

A dual-lens stereo camera with laser rangefinder measures bottle height (80–350mm) and diameter (50–120mm) in under 0.5 seconds. The system auto-adjusts guide rails and gripping strokes, supporting mixed production from 250ml mini bottles to 5L large formats.

Neck Orientation Stability System

Cone-shaped guiding wheels are tailored to 28mm standard neck diameters. This design limits neck deviation to ±0.5mm during buffering, ensuring >99.98% sealing success rate in downstream capping.

Hygienic Buffering Environment

Sterile Laminar Flow Shielding

Integrated H14-grade HEPA filters above the buffer channel create a vertical laminar flow (0.45 m/s), dynamically isolating it from the filling area. Airborne bacteria count is maintained below 1 CFU/m³, exceeding GB 8537-2018 hygienic standards for mineral water filling.

Residue-Free Track Design

The one-piece C-shaped guide rails are made from 316L stainless steel with mirror-polished inner surfaces (Ra ≤ 0.4 μm). Self-cleaning brush rollers allow CIP (Clean-in-Place) systems to flush out water residues and eliminate microbial dead zones.

Buffer Conveyor Typical Applications & Value

Scenario 1: Blow Molding – Filling Line Imbalance

During blow molding downtime (e.g., mold changes), the buffer can store up to 45 minutes of bottles at 1200 BPH. This prevents filler idle time and saves approx. 300 hours/year in unproductive downtime.

Scenario 2: Emergency Isolation in Downstream Packaging

If a labeler or shrink wrapper fails, the buffer releases bottles in FIFO order. Qualified bottles are redirected to temporary storage by robotic arms, reducing defective output by over 120,000 bottles annually.

Scenario 3: Synchronization in Large Bottle Lines

For 5L bottled water, where filler speed is only 200 BPH vs. 400 BPH at the blow molding stage, asynchronous dual-lane buffering resolves speed mismatch. Overall line utilization increases from 68% to 92%.